As a thermoplastic elastomer (TPE-O), Saxomer O impact is a physical alloy between the “rigid part” of polyolefin (PP) and the “flexible part” of POE, EPR or EPDM, with the addition of fillers and plasticisers.

Hardness: 35A – 60D | Density: 0.89 -1.25

This is why you should be using our TPE-O

As a thermoplastic elastomer based on styrene block copolymers (TPE-S), Saxomer S Flex is a physical alloy between a polyolefins (PS/PP/PE) “rigid part” and a styrene block polymers (SBS, SEPS, SEBS, SEEPS) “flexible part”, with the addition of various fillers, plasticisers and stabilisers.

Hardness: 0A – 65D | Density: 0.89 – 1.45

This is why you should be using our TPE-S (SEBS)

As a thermoplastic elastomer based on styrene-butadiene-styrene (SBS) block copolymers that have rubber-like attributes at room temperature, Saxomer T eco is easily processable. SBS is produced by adding various fillers, plasticisers, and stabilisers.

Hardness: 10A – 65D | Density: 0.89 – 1.40

This is why you should be using our TPE-S (SBS)

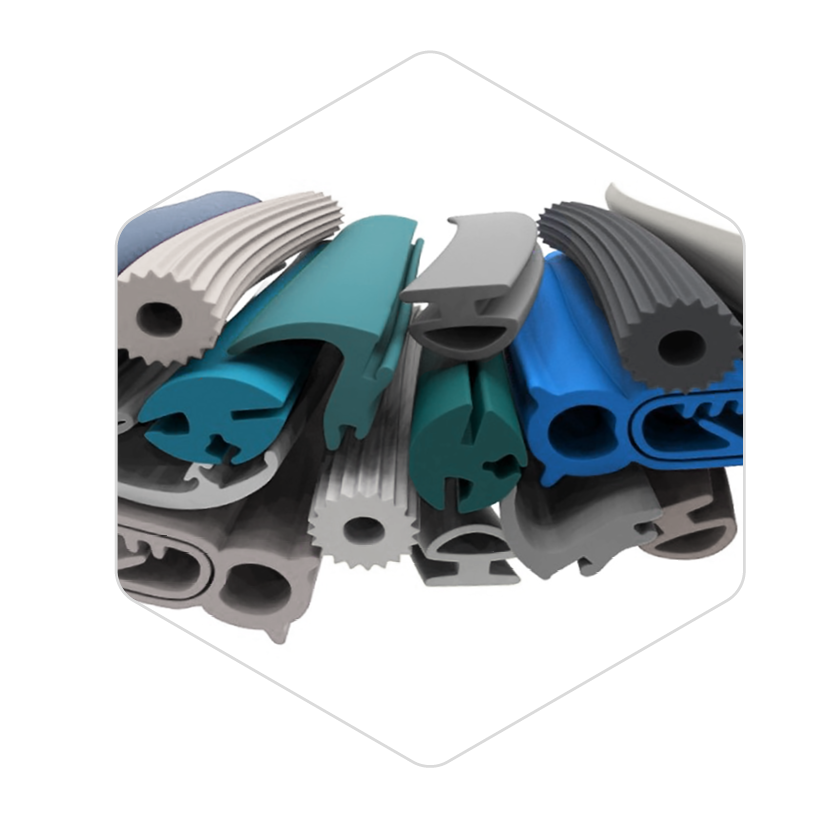

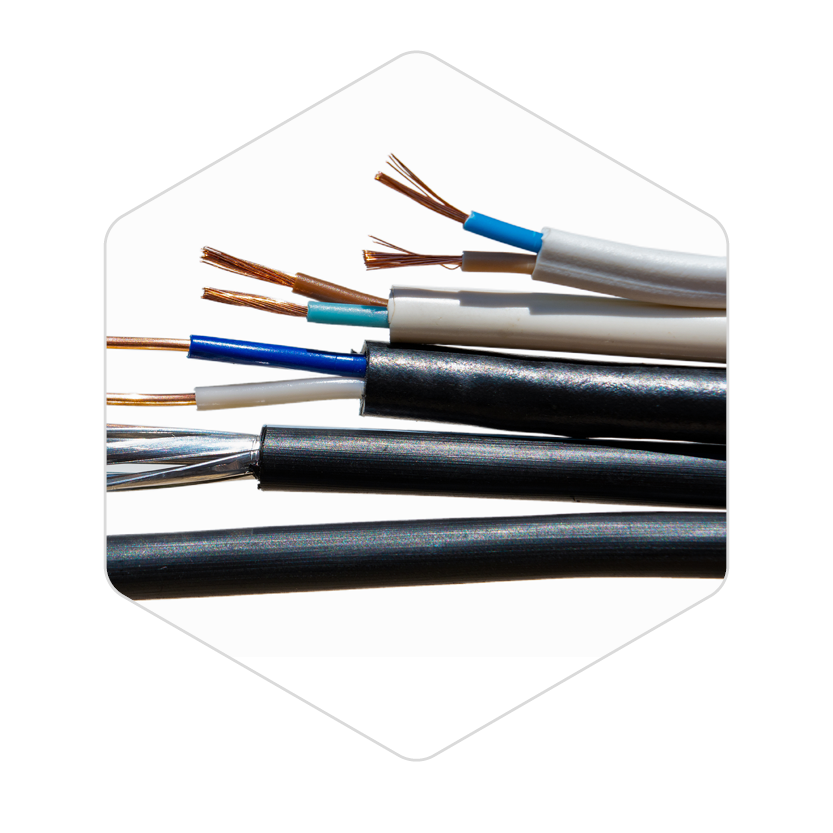

Use case examples

(TPO and engineering plastics)

©